|

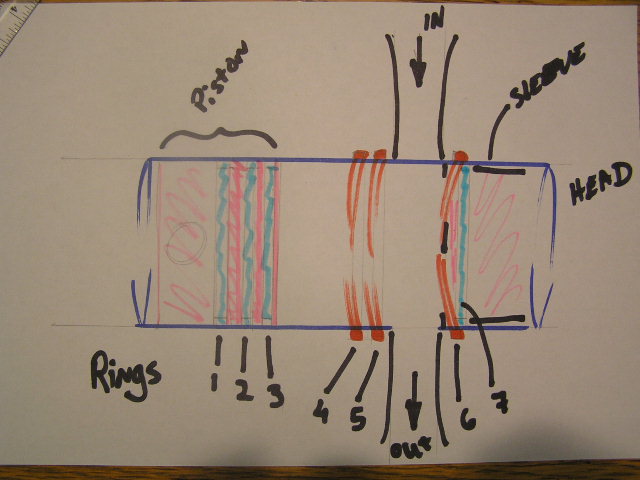

piston and sleeve rings

|

|

Piston and sleeve sealing design.

This is how I am moving forward.

|

|

I have two options here:

1. I can use conventional rings for all the applications, but then I will need to make the sleeve thick to carry the rings.

2. I can find rings that work in, instead of out. If I can find this tip of ring then I can have really thin walled

sleeve's

Paste this link, on this link you will see a Bristol Hercules sleeve and rings.

http://www.enginehistory.org/G&jJBrossett/Coventry/Bristol%20Hercules%20sleeve%20down.JPG