|

Heads

|

|

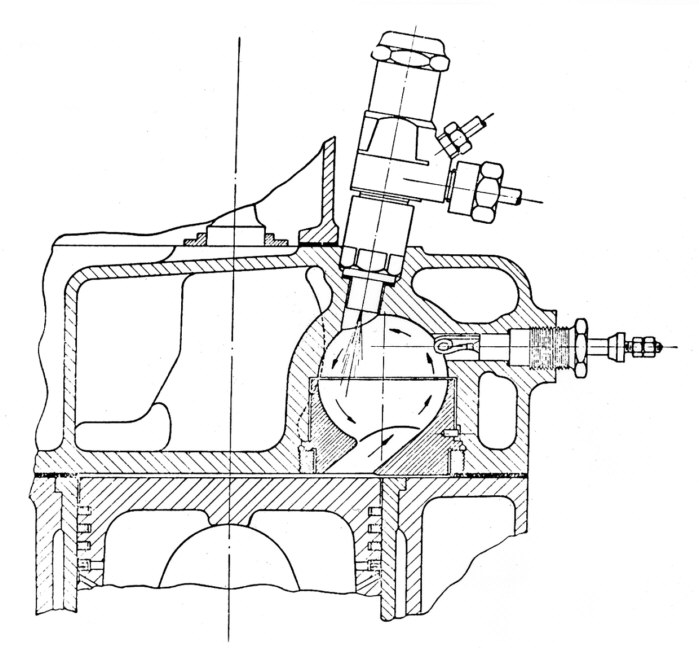

Now that I will use the WV 1.9 piston it has a recess built in to it and as such the Junk Head need not have a recess. Therefore

the junk head will be flat or will have a hump that protrudes in to the piston cavity.

|

|

Enter supporting content here