|

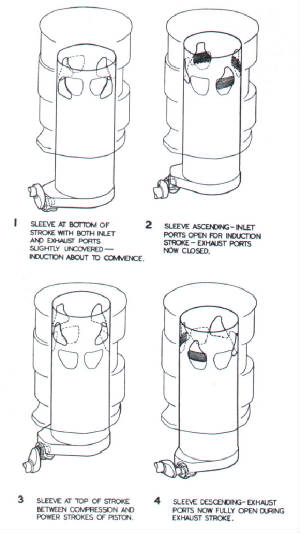

Cylinder ports of a Napier engine with the head closest to you.

Historically sleeve valve engines have had high oil consumption.

This is how I propose to over come this problem:

The first option I have is to put a, custom made oil scraper seal on the end of the rotating sleeve, (this oil scraper

would have to scrap the wet liner as well as the head) and have the head whet beyond that. In this way relay on the little

oil that is trapped in the grinding valleys. (The sleeve will have to be ground all the way to the top on the in side and

the out side, as well as the wet-line cylinder head.)

The next option, with is the one I favour is:

Realising the sleeve is acting like a valve in side the cylinder I will use this valving action in side the head to pump

exhaust fumes from the exhaust port side, into the inlet manifold.

I will also introduce a little oil, in to the head that can then be burnt of in the cylinder.

Enter subhead content here

|